What is a Speed Governor?

The speed governor is responsible for keeping the generating unit at a constant speed so that the frequency of the generated voltage is maintained at its nominal value.

To achieve this, it acts on the water flow that flows to the hydraulic turbine.

Since the power generated is a direct function of the turbine’s flow rate, the speed governor also plays a fundamental role in controlling active power when the generating unit is operating synchronized with the electrical system or supplying an isolated load.

A modern speed governor has two main components: digital control (RVX POWER) and hydraulic power (FLUIDPOWER).

Speed Governor | RVX

The RVX POWER Speed Governor is based on REIVAX’s most advanced platform, designed to ensure high performance and reliability.

It controls frequency and active power and can be applied to Pelton, Francis, Kaplan, and Bulb turbines.

Its modular design, expandability, and configurable software allow it to meet the most varied requirements and specificities of each application. It can also monitor and automate the Hydraulic Power Unit (HPUX).

Certified to the main electromagnetic compatibility standards and built specifically for the most demanding segments, the system operates in highly aggressive environments.

RELIABILITY AND ROBUSTNESS THROUGH DESIGN

The RVX POWER hardware, software, and interface tools are identical for any size and type of hydraulic turbine (Francis, Kaplan, Bulb, or Pelton). Furthermore, the controller hardware and software tools are identical to those used in the RTX POWER Excitation System, simplifying testing, operation, and system maintenance.

Testing is significantly facilitated by the RVX POWER’s intuitive graphical interface, which features a graphical representation of the transfer function, a built-in step response tool, online oscillography, and the ability to change closed-loop control parameters, all within a single tool.

With high control precision, the RVX POWER Digital Governor has a reduced frequency deadband, detecting even small variations.

The total dead time, including typical hydraulic delay, meets the requirements of the most demanding Network Procedures in the world.

REDUNDANCY

The RVX POWER Digital Governor offers a variety of redundancy options, such as a redundant controller, redundant I/O unit, redundant frequency sensors, etc. Even in designs without redundancy, the RVX POWER system has a very high MTBF.

REIVAX’s extensive knowledge of hydraulic systems, concentrated in the FLUIDPOWER line, and its experience in advanced control algorithms ensure high-performance control and reduce actuator wear in any type of turbine (Francis, Pelton, Kaplan, or Bulb).

SPECIAL FEATURES

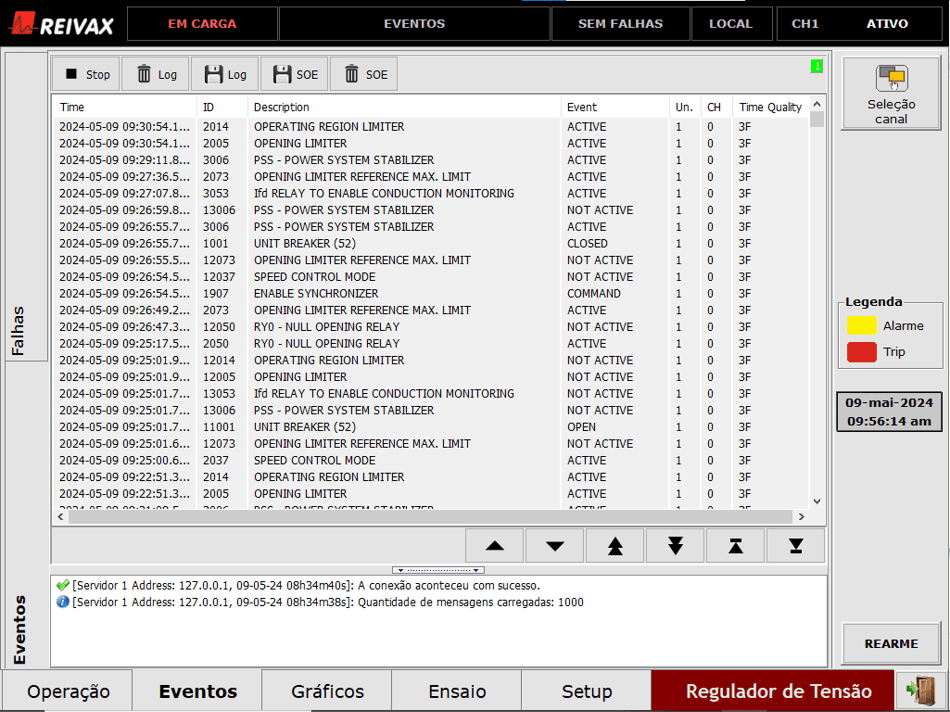

SIGNALS RECORDER AND EVENTS RECORDER (SOE)

Coordination with other plant events is easily accomplished by synchronizing the RVX POWER with an IRIG-B, NTP, or PTP signal, and utilizing the high-frequency sampling capabilities (less than 1 ms) of the REIVAX datalogger.

A special feature of the signals recorder includes eight (8) triggers for pre- and post-event recording, allowing customers to visualize system behavior after an event (alarm or trip).

COMMUNICATION INTERFACES

The RVX POWER easily communicates with the SCADA automation system via IEC 61850 GOOSE/MMS, DNP3.0, IEC 104/101, or Modbus TCP/IP protocols. Consult REIVAX for other protocols.

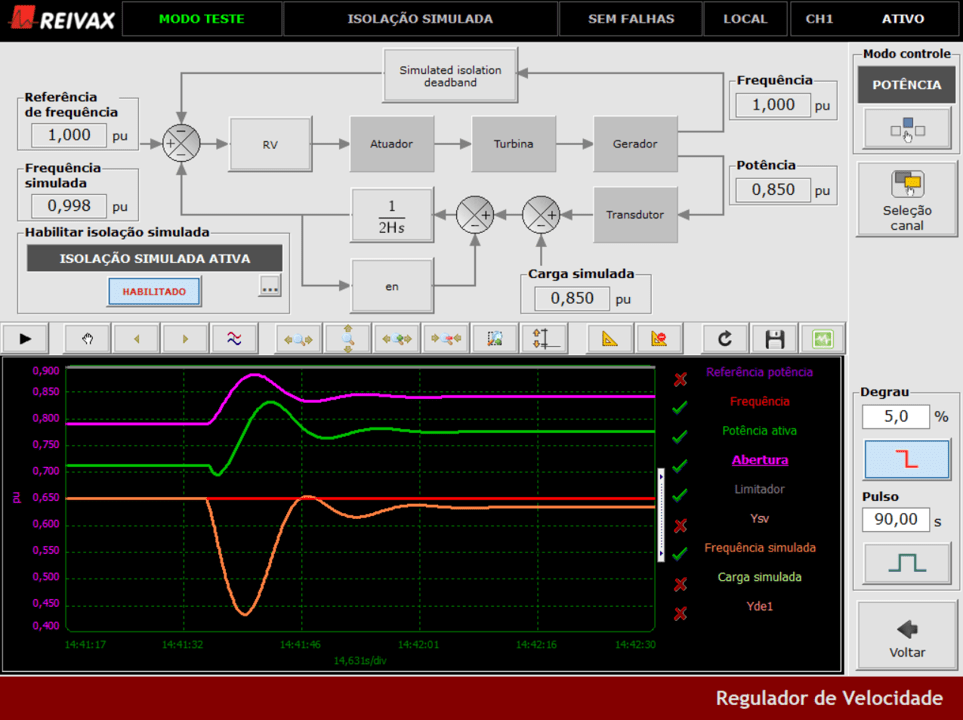

GOVERNOR TUNING – SIMULATED ISOLATED NETWORK

The dynamic response of the Governor can be optimized for different operating conditions using the Simulated Isolated Network tool. This functionality is based on IEC 60308 and IEEE 1207 standards and is already available in the RVX POWER software.

After adjusting the control loop in the field using the Simulated Isolated tool, the generating unit will be reliable for operation in both an interconnected system or isolated system, without any switching between control loops, which can cause instability.

OPEN PROGRAMMING

Open programming allows the addition of advanced control algorithms, such as adaptive power and level control, oscillography, servomotor optimization, etc. Users have full control to make changes to the software or add new analog or digital interface points.