Power Plant Controller + SCADA | PPC

Reivax’s Power Plant Controller (PPC) offers a unique environment for the coordinated control and operation of assets involved in renewable energy generation and storage, such as: capacitors/inductors and transformers.

The PPC is responsible for ensuring compliance with the grid connection criteria for the power plant, and its presence is mandatory in centralized renewable power plants. Optionally, it guarantees an appropriate voltage band for local loads within the plant, supplied by the power plant itself at low and medium voltage levels.

SCADA | SCX

A Supervisory Control and Data Aquisition (SCADA) system encompasses hardware and software that monitor and control power plant equipment. SCADA collects and processes real-time operational data, interacts directly with process equipment, stores values and events locally, and enables the transmission of this data to high-level systems.

SCADA systems are used in a wide range of applications; in Reivax’s case, they are applied to the control and supervision of the power generation process.

PPC PV

The PPC PV specifically coordinates solar inverters (Centralized or String) and other PPCs, organizing the joint operation of the equipment, enabling the plant to achieve its objectives regarding the connection point with the electrical system, in compliance with the Grid Code.

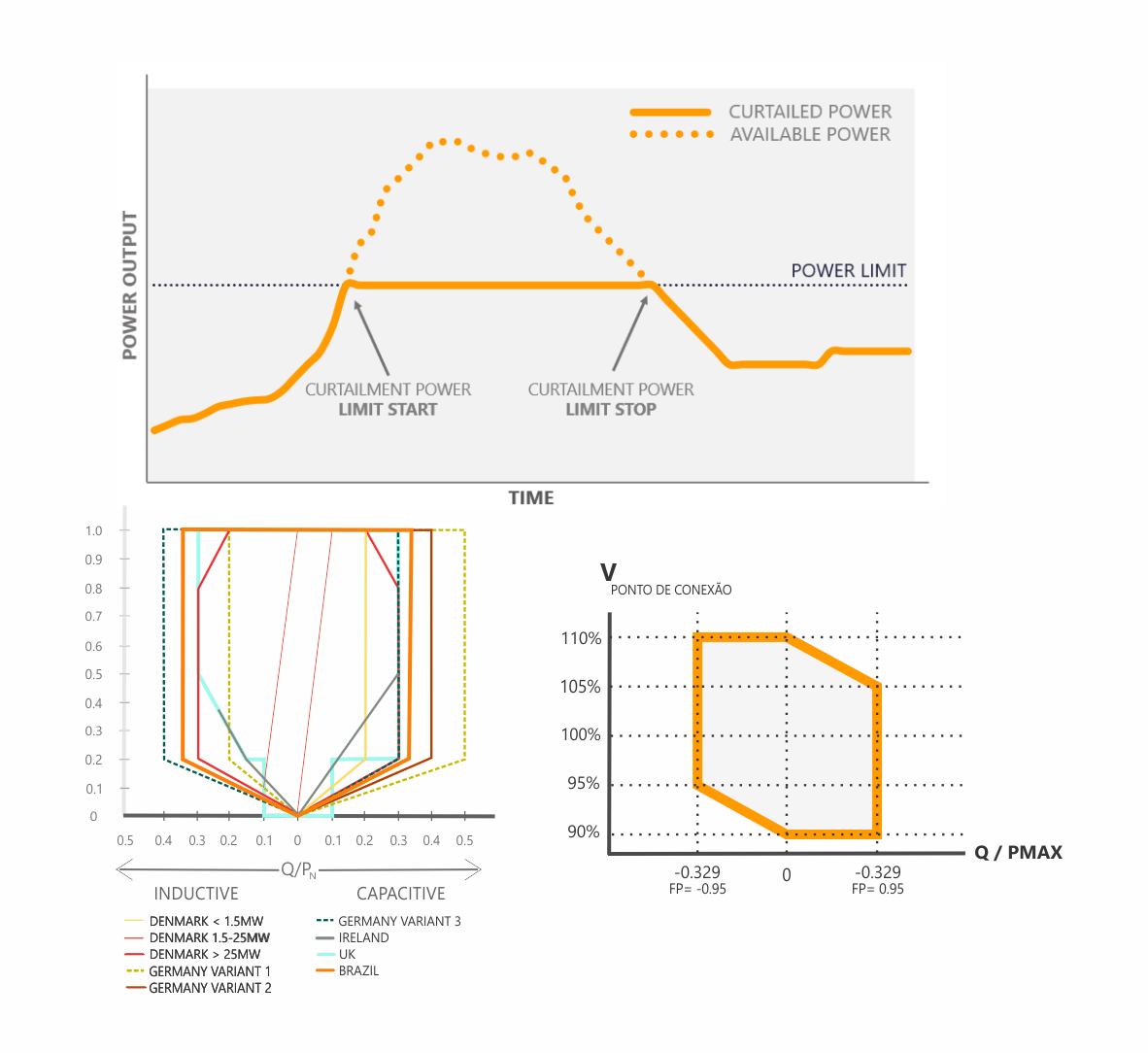

COMPLIANCE WITH GENERATION RULES

Modos de controle no ponto de conexão:

- Active Power: Fixed or frequency-dependent;

- Reactive Power: Fixed or voltage-dependent;

- Power Factor: Fixed or active power-dependent;

- Voltage: Fixed or static.

OPTIMIZATION OF ENERGY GENERATION

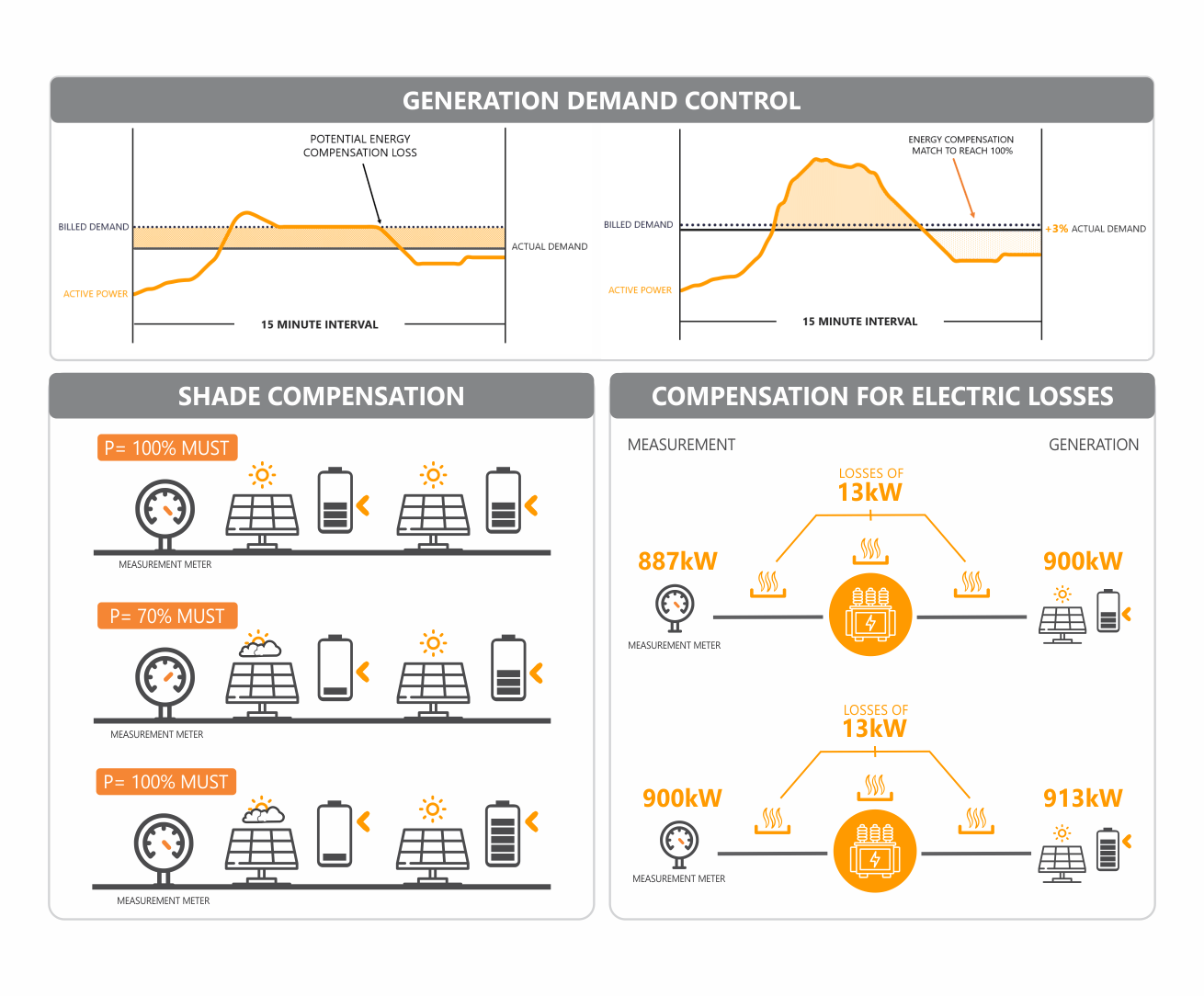

GENERATION CONTROL ON DEMAND

Maximization of the utilization of contracted demand, increasing generation while there is excess demand to be used (billed demand).

SHADING COMPENSATION

When a module has a generation deficit, the PPC commands an increase in the generation of other modules in the same cluster, thus allowing for the compensation of this deficit and maintaining high generation levels for the cluster.

COMPENSATION FOR ELECTRIC LOSSES IN THE PLANT AND LOCAL LOADS

Generation targets compensate for the electric losses present in the plant and local loads, allowing for increased generation at the connection point.

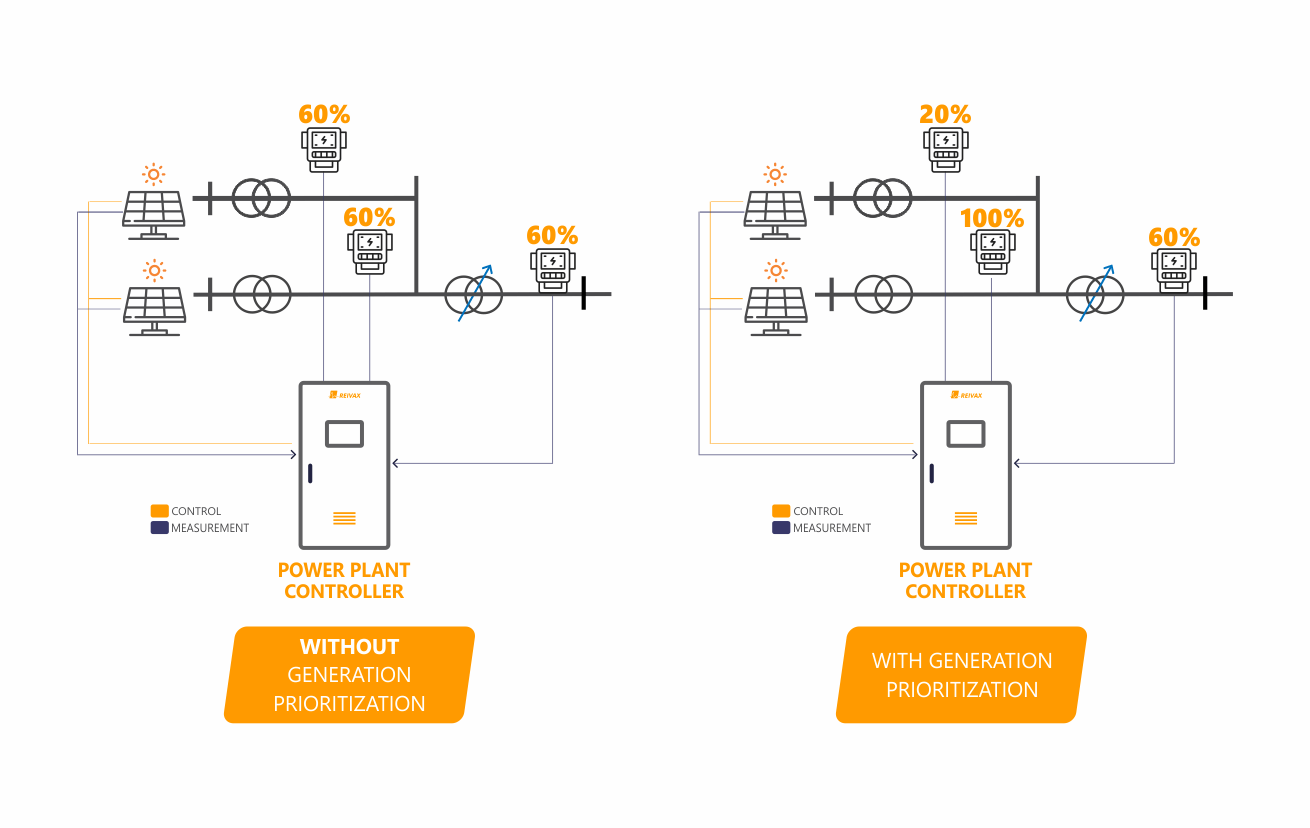

PRIORIZATION OF GENERATION BY EACH SOLAR PLANT

During curtailment situations, it is necessary to reduce the plant’s power, which can be done either equally or by prioritizing certain power plants. Prioritization is particularly important when the parks have distinct generation contracts, allowing for one contract to be favored over another according to its relevance and contractual needs.

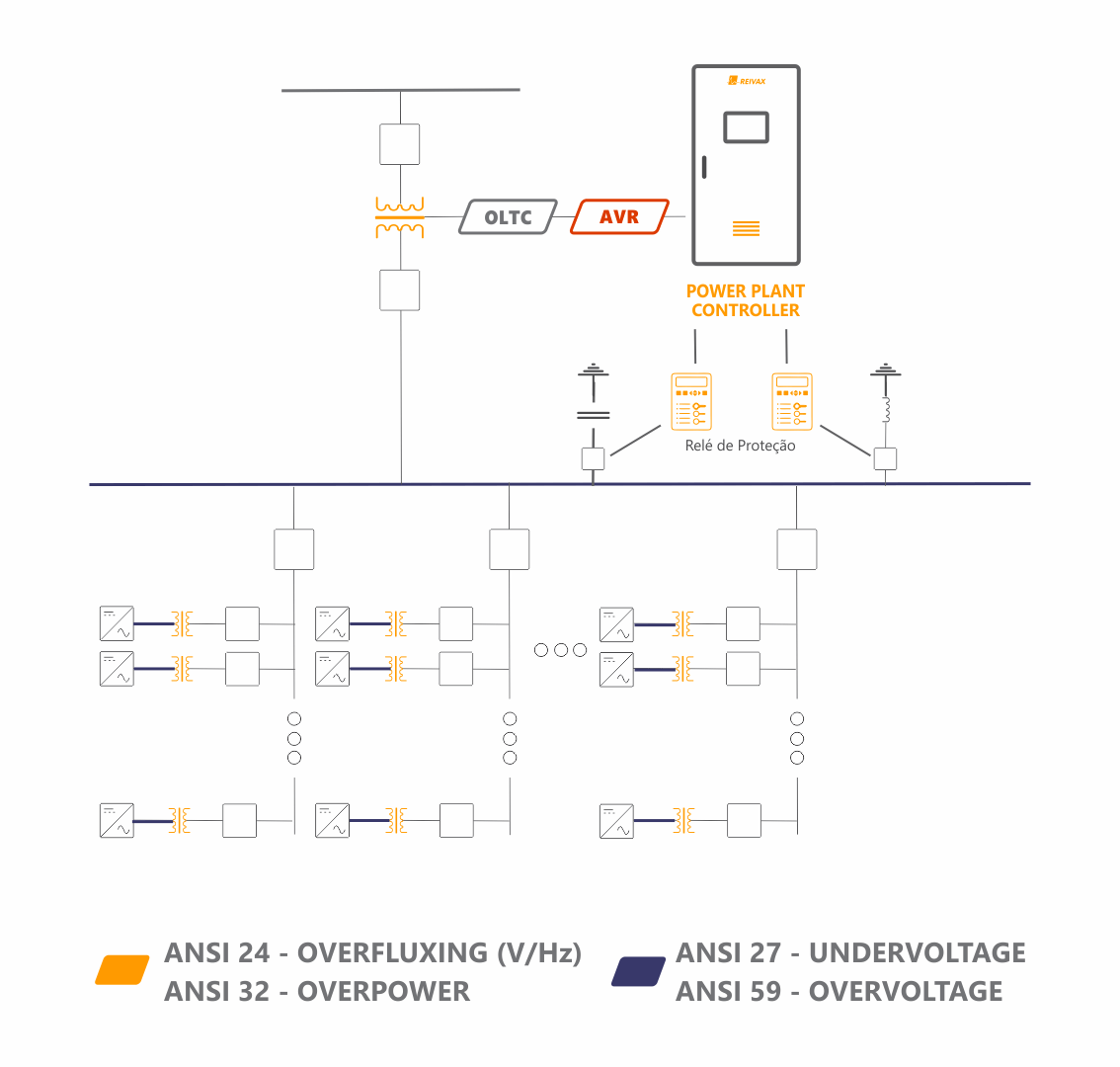

JOINT AND COORDINATED CONTROL OF THE OTHER PLANT ASSETS

CAPACITORS/INDUCTORS AND TRANSFORMER TAPS

Automated connection/disconnection of capacitor/inductor banks and automated switching of the tap changer position on the step-up transformer.

DYNAMIC OVERMAGNETIC FLOW LIMITERS (ANSI 24) AND MAXIMUM POWER LIMITERS (ANSI 32)

To prevent unfavorable conditions in the transformers. Additionally, there are dynamic undervoltage and overvoltage limiters (ANSI 27/59) for medium voltage lines and generator outputs, aiming to comply with the operating limits of auxiliary loads.

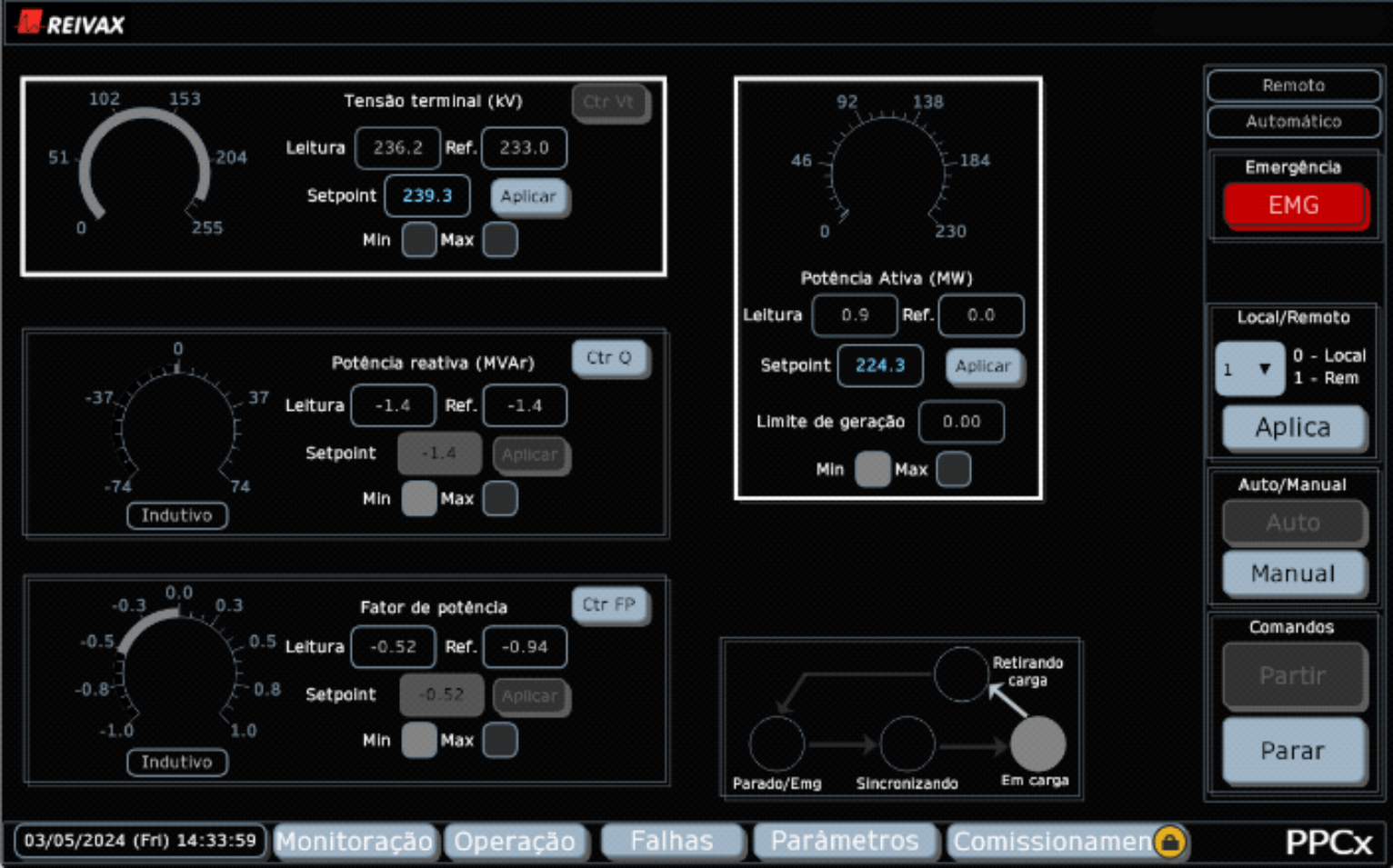

IHM & SCADA

EASE OF USE AND SIMPLIFICATION FOR OPERATION AND MAINTENANCE

HMI and SCADA in compliance with ISA-101 (Human Machine Interfaces for Process Automation Systems), facilitating operation and maintenance.

SCADA is a tool for both local and remote use, while HMI focuses on local operation.

TECHNICAL FEATURES

COMMUNICATION INTERFACE

Ethernet

Single-mode or multimode fiber optic

RS 485

PROTOCOL

INDUSTRIAL

Modbus TCP, Modbus RTU, IEC 60870-5-101, IEC 60870-5-104, IEC 61850, DNP3, OPC DA, OPC UA, Profibus DP, Ethernet IP

NETWORK

VLAN (IEEE 802.1Q), QoS (IEEE 802.1D), RSTP (IEEE 802.1w) and MRP

CONTROL PANEL

POWER SUPPLY

125 V DC / 100-240 V AC (optional)

UPS

24 V DC, 5A 7,2 Ah (optional)

IP RATING

IP54 (sheltered)