SCADA | SCX

A Supervisory Control and Data Acquisition (SCADA) system comprises hardware and software that monitor and control plant equipment.

A SCADA system collects and processes real-time data from operations, interacts directly with process equipment, stores values and events locally, and allows this data to be sent to higher-level systems.

SCADA systems are used in various applications; in the case of REIVAX, for supervision and control of generation processes.

|

|

|

Hydropower PlantsSupervisory solution for SHPs, HPPs, and Step-up Substations connected to the grid. |

Wind Power PlantsSupervisory solution for wind turbines, PPC integration, collector substation, and grid connection bay. |

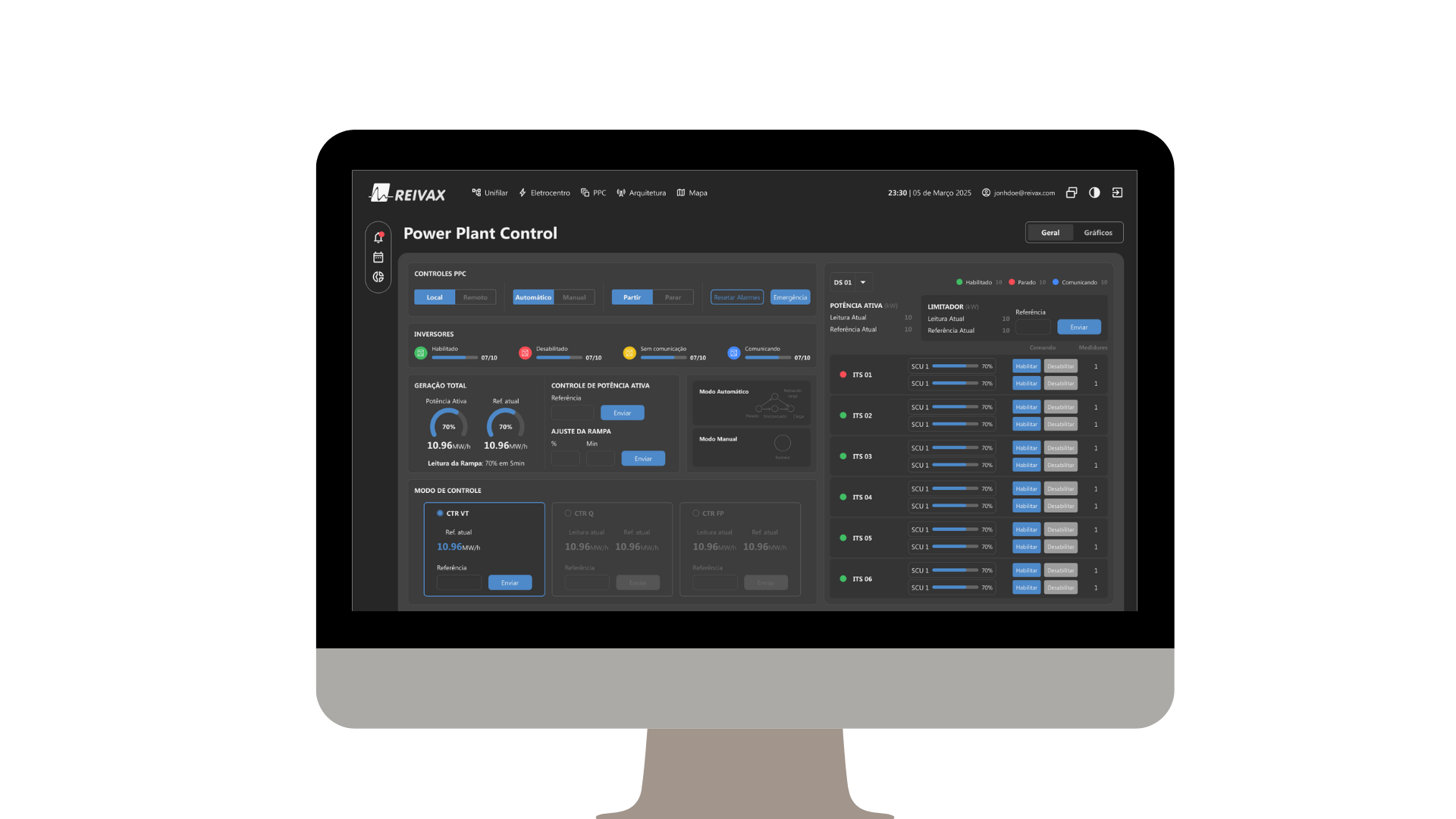

Solar Power PlantsSupervisory solution for centralized generation (CG), covering inverters, trackers, weather station, native PPC integration, collector substation, and grid connection bay. |

REIVAX | WEG GroupA REIVAX dá mais um passo em sua trajetória com o lançamento do novo site — mais moderno, intuitivo e conectado com o que somos hoje. |

SCADA COMPONENTS

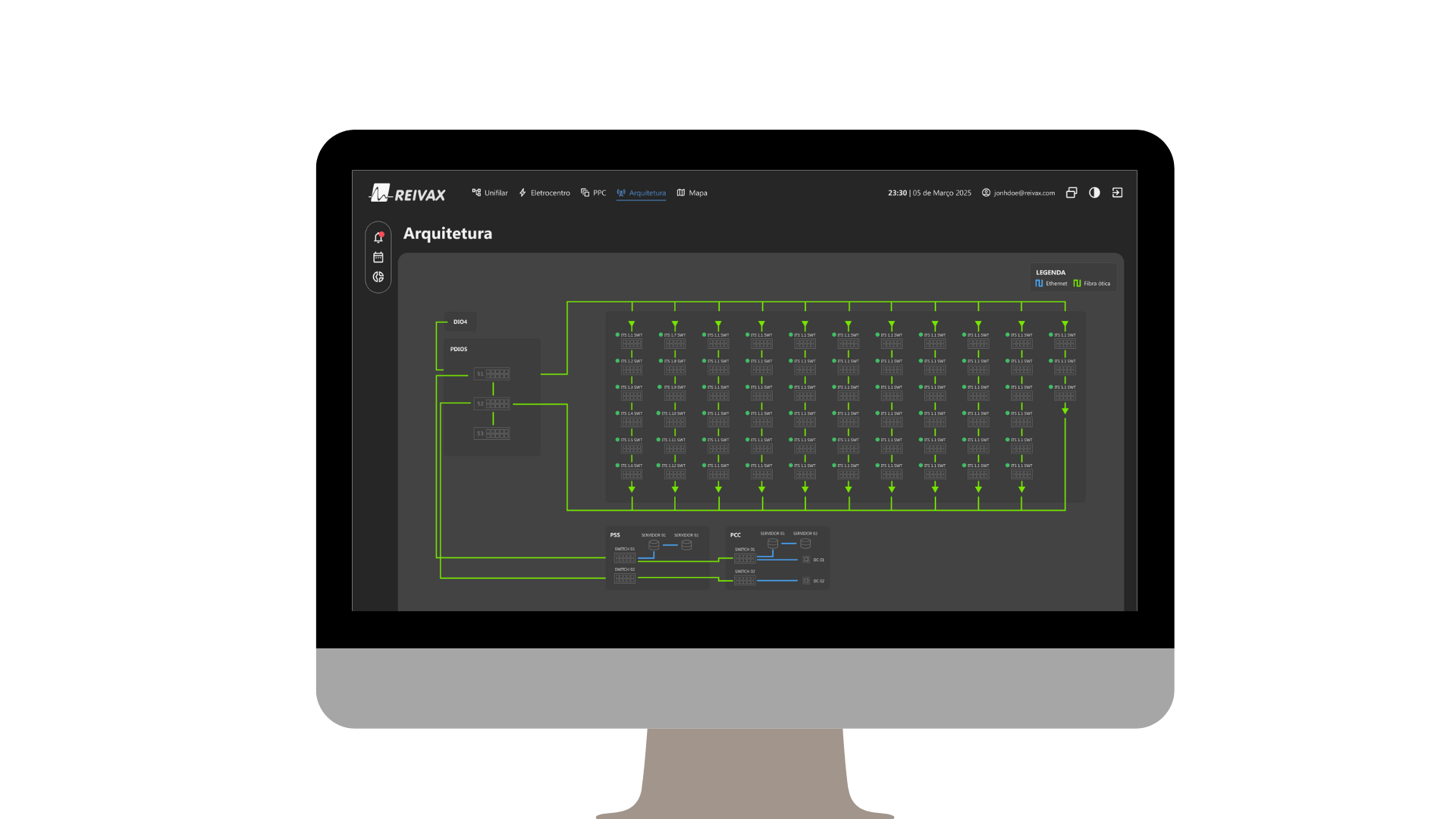

1. Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs) are self-contained processing devices installed in the plant. They control and interface with local processes and route data to the SCADA server. They also receive control commands from the SCADA server and relay these commands to field devices. Many RTUs store data in their local database and provide it to the SCADA system when requested.

2. Servers are dedicated computers that communicate with RTUs and PLCs. They initiate all communication, collect and store data, provide graphical interfaces for users, and send information to other systems. They perform alarm processing, trend graphing, and report generation functions.

3.The communication network provides the link between field RTUs and PLCs and the SCADA servers in the control center. This communication uses various media such as twisted pair cables, coaxial cables, fiber optics, satellite, high-frequency radio, etc. Ethernet switches, GPS clocks, optical splitters, among others, are also part of the communication network.

4.Workstations display data to the user and allow interaction with the process. In short, they provide operators with a graphical representation of field variables, alerts and alarms for operational conditions, and record analog and discrete variables in a database.

FEATURES

INTEROPERABILITY

HIGH-PERFORMANCE INTERFACE

CUSTOMIZATION

OPTIMIZATION

MOBILE

CYBERSECURITY

FLEXIBILITY